Product development

产品研发

Structural design

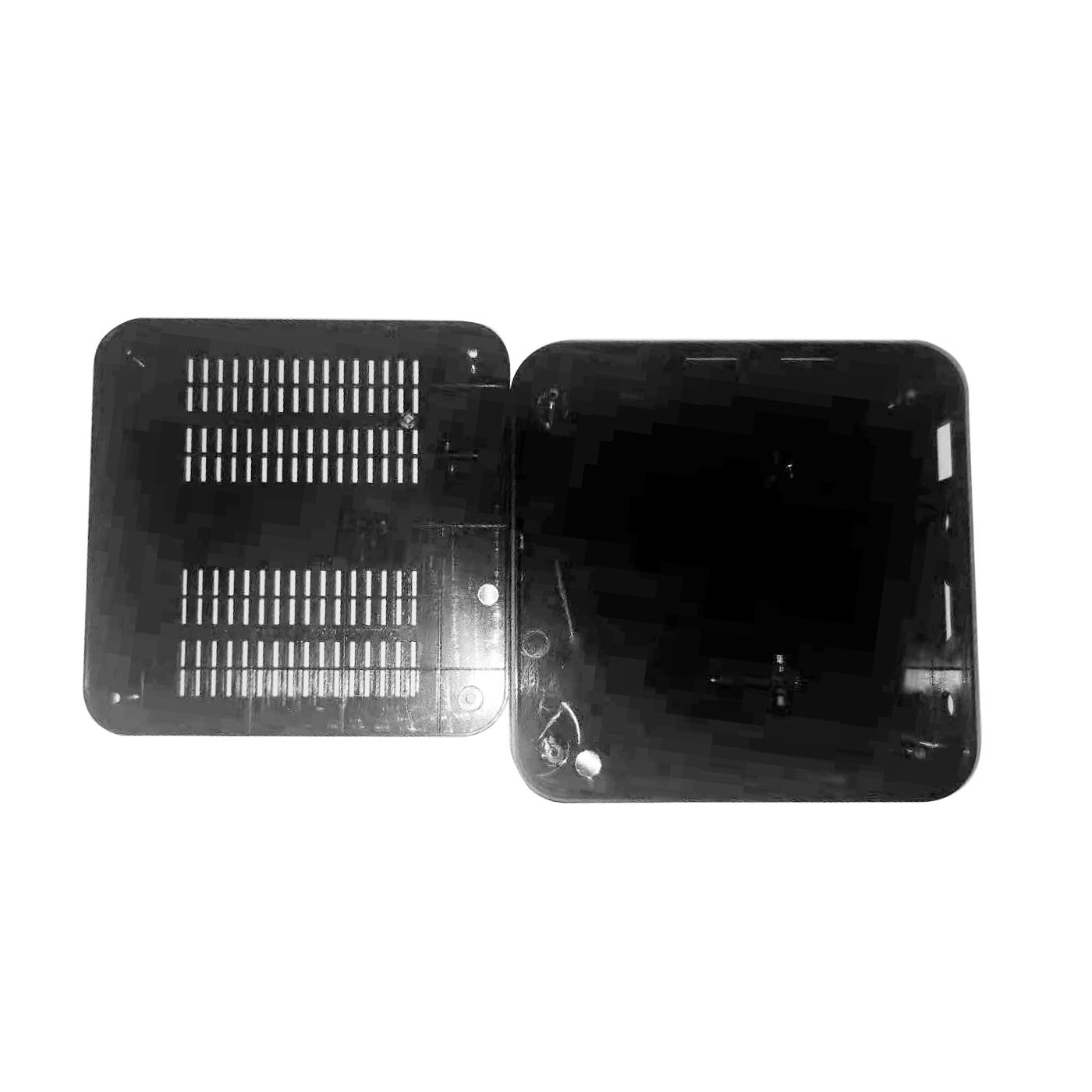

If there is no problem in the appearance design, 3D software can be used to make the structure and functional mechanism of the product, and the design effect can also be rendered after completion.

Structural design steps

S1: ID review S2: Cost control evaluation and accounting S3: Structural scheme design and assembly relations S4:Structure 3D drawing design and internal review Structural engineers will evaluate the feasibility of structural design for the ID scheme selected by customers, design of component structure stacking, structural 3D modeling (demoulding elements, definition of parts disassembly), parts disassembly, appearance confirmation after disassembly, product internal structure detailing (parts arrangement, positioning, connection, assembly, etc.), and component interference analysis. Motion simulation analysis, product reliability analysis (dustproof, waterproof, shockproof, heat insulation, heat dissipation, etc.), structural design 3D drawing review, final review, drawing optimization and confirmation. S5:2D drawing and BOM preparation and internal review parts 3D to 2D (PCB, die casting 2D, stamping parts, sheet metal parts, machine parts, profiles, etc.), product Bom material list preparation (product model, name, specification, single weight, material, dosage, surface treatment), hand board production review, pre-die meeting. S6: Process drawing design S7: explosion drawing and assembly drawing design.