Production equipment

Injection molding

machine

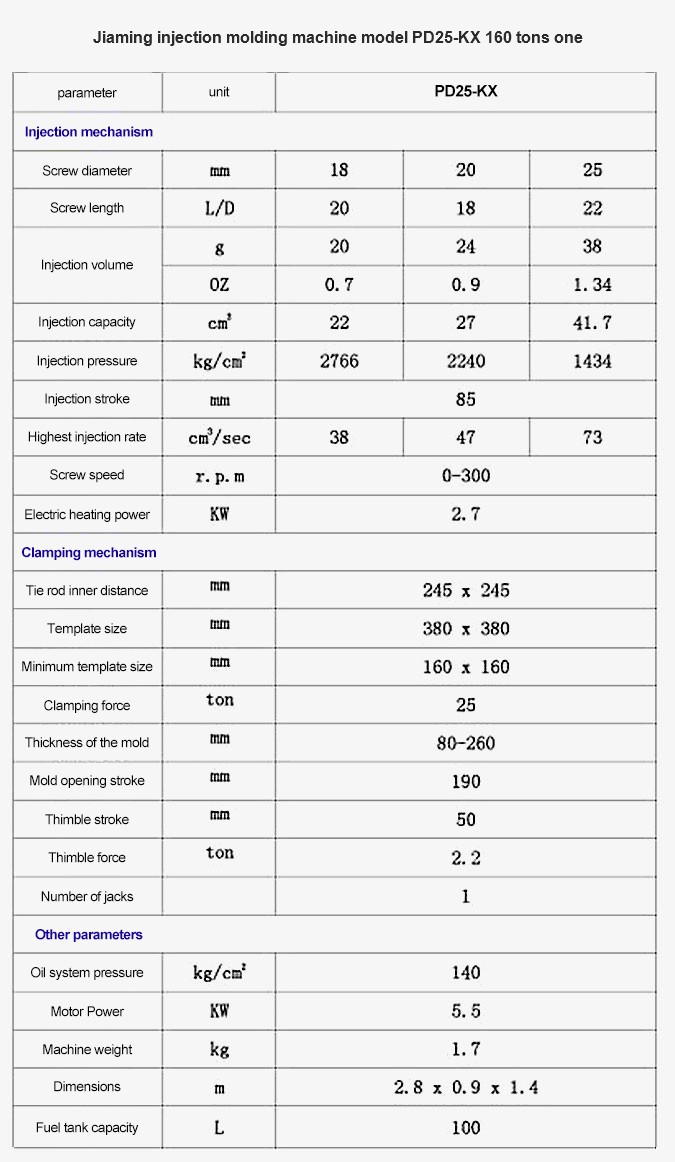

Injection molding machine

Production capacity 20 Electrical power rate 30

Overall dimensions 2.0+2.3+10 Type of plastic machinery Injection molding machine

It is suitable for the production of large hardware packaging, such as AC plug, tool handle packaging, sole packaging, and auto parts insert packaging, secondary packaging molding

To meet users' higher requirements, with modular, easy maintenance, energy saving, durable, high speed, precision as the design concept, to create a high-performance servo injection molding machine on a new platform. KX series servo injection molding machine adopts comprehensive optimization of the locking unit, equipped with high strength joined template, with modular injection unit design, can provide a variety of collocation scheme for users to choose, to meet the diverse needs of users.